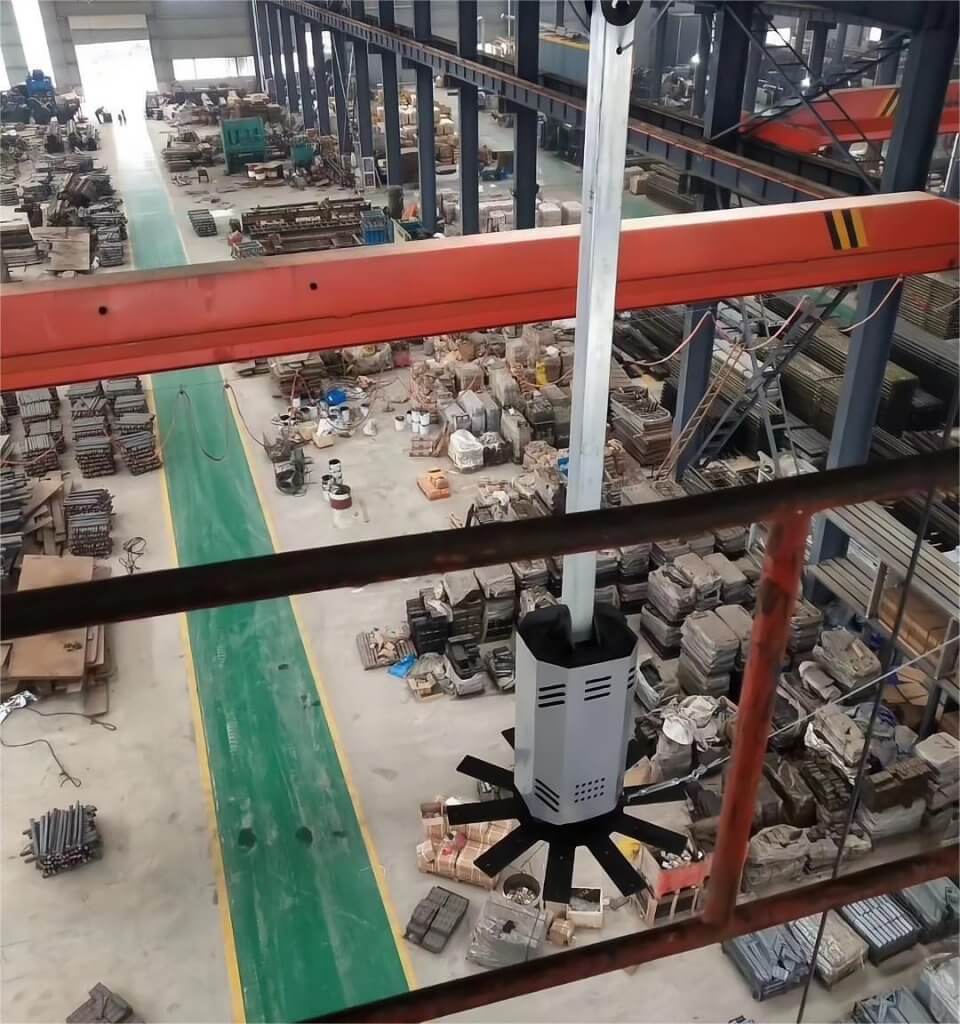

In industrial settings, managing temperature is crucial for both productivity and worker comfort. An HVLS (High Volume, Low Speed) fan matrix is increasingly recognized as an effective solution for cooling large factory spaces efficiently. These large ceiling fans operate by generating a massive, gentle air movement, distributing air evenly throughout the space.

The strategic placement of multiple HVLS fans in a matrix setup can significantly enhance the cooling effect. This arrangement allows for the creation of a continuous airflow pattern, which effectively reduces hot spots and ensures a uniform temperature distribution. The result is a cooler, more comfortable environment that can improve worker performance and reduce the need for expensive air conditioning systems.

HVLS fan matrices are not only beneficial for cooling but also energy efficient. By moving large volumes of air at a low speed, they consume significantly less energy compared to traditional cooling methods. This makes them an environmentally friendly and cost-effective option for industrial cooling needs.

Implementing an HVLS fan matrix can transform the cooling strategy of any factory. It provides a scalable and flexible solution that can be adapted to various industrial layouts and sizes, ensuring optimal cooling performance across the board.